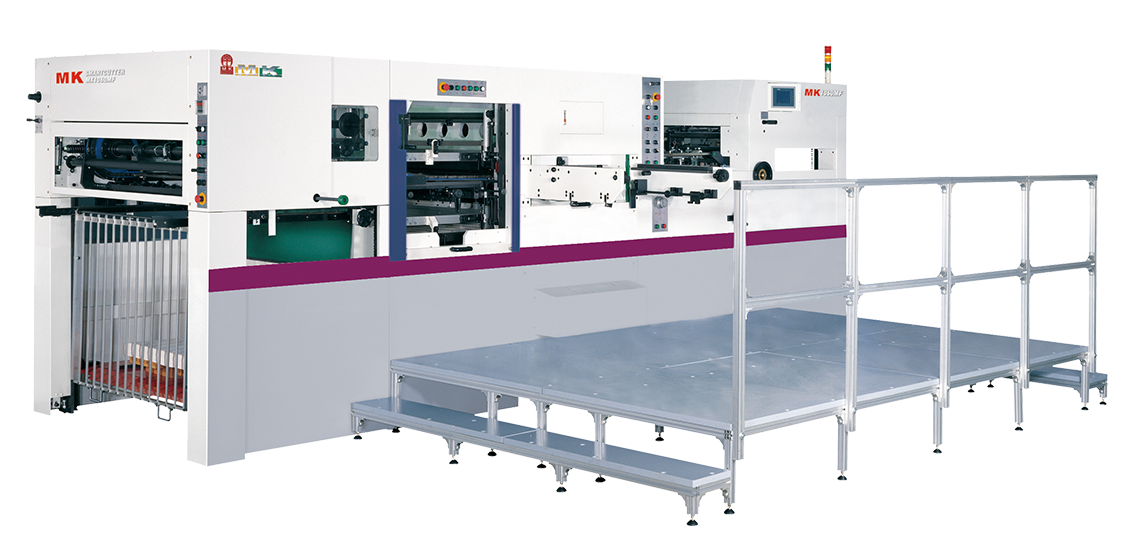

1060YMI Foil Stamping Machine

Advanced foil unwind system

Feeder

The foil unwind system is equipped with 3 advance shafts (standard configuration).This ensures smooth, accurate foil feeding with excellent tension control properties. The used foil removal brushes are controlled with high quality imported servo motors. The honey- comb base is made of special thermal resistant materials. The heated bed consists of 20 heating zones which gives accurate heating properties on complicated foil stamping jobs.

3 devices prevent feeder from crashing. Lateral manual adjustment device for feeder pile. The powerful feeder is equipped with 4 lifting suction cups and 5 transport suction cups; the lateral direction of suction cups are adjustable according to the paper deformation. Blowers on both sides of the feed system separate the product for a smooth feeding process.1060YMI equips the two-directional electrical fine adjustment to give easier operation.

Platen Press Section

The worm wheel and worm set products are imported from Taiwan whilst the crankshaft is manufactured in our own machining center. The key transmission parts provide our customer with reliability and durability. The platen walls and base are made of ductile iron in line with British Meehanite casting standard.

Stamping Section

The foil unwind system is equipped with 3 advance shafts (standard configuration).This ensures smooth, accurate foil feeding with excellent tension control properties. The used foil removal brushes are controlled with high quality imported servo motors. The honey- comb base is made of special thermal resistant materials. The heated bed consists of 20 heating zones which gives accurate heating properties on complicated foil stamping jobs.

The VMP2005 stamping control program, working on Windows XP, was developed by Masterwork Machinery (intellectual property right: 2008SR05319). The man-machine interface has a user-friendly operation. All electric controls are designed in the program. The program can handle complex foil advance calculations. With the precise calculation, the program efficiently improves foil usage. The hologram foil stamping accuracy is ≤±0.2mm. The system accurately controls the foil advance devices, the system can feed foil from a 740mm maximum to a 1mm minimum even running at high speed

Contact us for more information

SPECIFICATIONS

See what the MK1060YMI can do

| Max sheet size | 1060mm x 760mm |

|---|---|

| Min sheet size | 450mm x 360mm |

| Max die cutting size | 1045mm x 745mm |

| Max stamping size | 1020mm x 730mm |

| Gripper margin | 9~17mm |

| Inner chase size | 1120mm X 786mm |

| Stock range | 90~2000g/m2 paper / 0.1~2mm paper / ≤4mm corrugated |

| Die cutting accuracy | ≤±0.075mm (Die cutting and stamping ) / ≤±0.20mm (Hologram stamping ) |

| Max die cutting force | 320 tons |

| Max die cutting speed | 6500s/h Stamping – 5500s/h Hologram stamping or laser seam prevention – 7700s/h Die cutting |

| Max feeder pile height | 1150mm (wooden pallet included) |

| Max delivery pile height | 1000mm(wooden pallet included) |

| Widest dimension of in longitudinal/ transversal | φ250mm |

| Number of heating zones | 20 heating / 40°C~180°C Adjustable |

| Dimension of the foil | 20~1020mm |

| Overall dimension | 7230mm(L:Pre-load paper device included) x 4550mm(W:Platform included) x 2050mm(H) |

| Net weight approx About | 17 tons |

| Main motor wattage | 11kw |

| Full load wattage | 50.6KW |