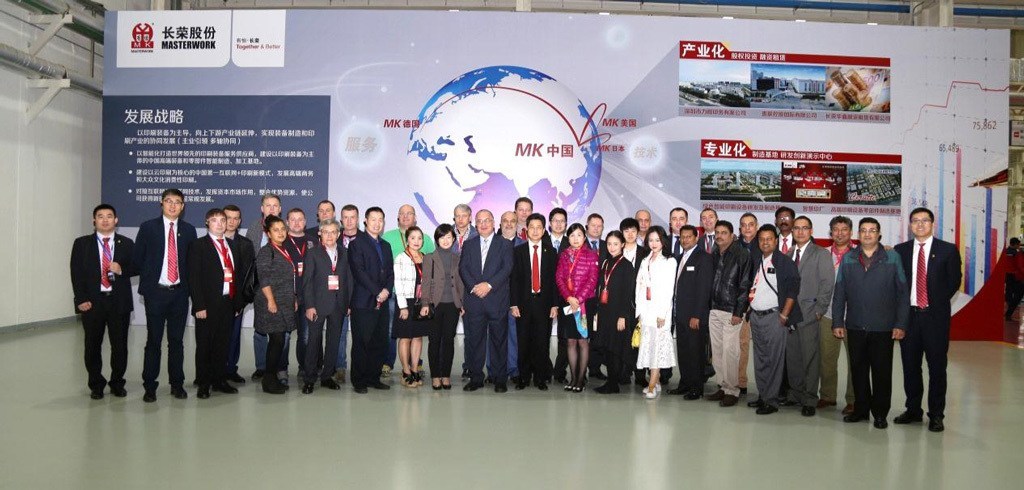

The combination of Masterwork Machinery and scientific innovation

July 29 afternoon, after careful preparation, our company hosted the signing ceremony of the famous laser and nonlinear optics expert, Dr. Yao Quan. Dr. Yao is presently a well known Professor of Tianjin University and Academician of Chinese Academy of Sciences.

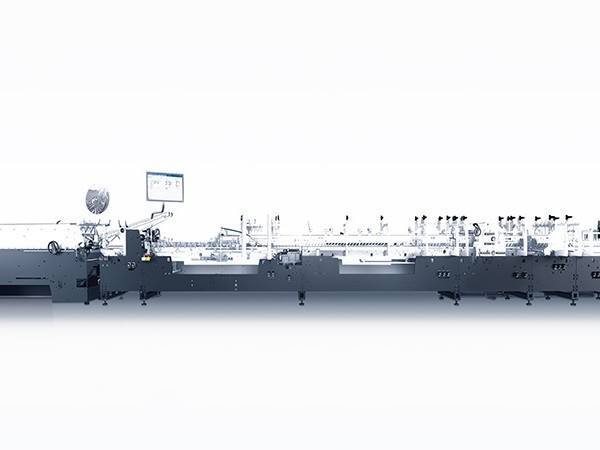

Masterwork Machinery China invited Dr.Yao Quan to become chief scientist at the company. The enrollment of Dr.Yao is to supervise and advance research in “Digital Die Cutting and foil stamping”, “High-speed laser die-cutting” and “Automation “technologies with Masterwork Machinery. With Dr.Yao’s expertise and contribution, Masterwork Machinery is looking for turn concepts into reality, to become one of the leaders in the digitalized post-print industry.

Dr.Yao Quan mentioned, in a new research direction in addition to our current projects, we will be adding additional research in Laser Photonics technology and terahertz technology to improve further possibilities in R & D.

Masterwork and Dr. Yao Quan will combine business with scientific and technological innovation to establish cloud printing technologies, high- speed digital printing and finishing technologies and to further improve Masterwork’s competitive strength.